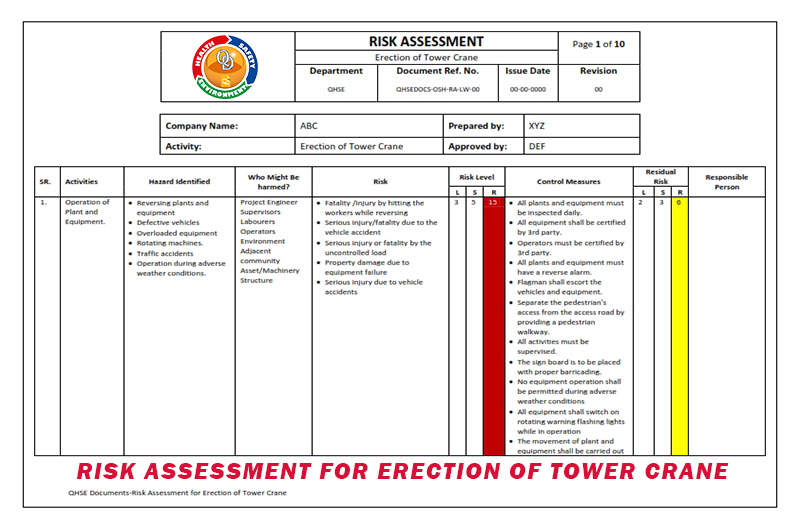

This document” RISK ASSESSMENT FOR ERECTION OF TOWER CRANE” uploaded by QHSE Documents is in ready-to-use and editable Word format. The original file for the erection of the tower crane and risk assessment is prepared under the following categories and its related main points:

Activity No.1: Operation of Plant and Equipment.

Hazards

1. Reversing plants and equipment

2. Defective vehicles

3. Overloaded equipment

4. Rotating machines.

5. Traffic accidents

6. Operation during adverse weather conditions.

Risk

1. Fatality /Injury by hitting the workers while reversing

2. A Seriou’s injury/fatality due to the vehicle accident

3. A Seriou’s injury or fatality by the uncontrolled load

4. Property damage due to equipment failure

5. A Seriou’s injury due to vehicle accidents

Control Measures

1. All plants and equipment must be inspected daily.

2. All equipment shall be certified by 3rd party.

3. Operators must be certified by 3rd party.

4. All plants and equipment must have a reverse alarm.

5. Flagman shall escort the vehicles and equipment.

6. Separate the pedestrian’s access from the access road by providing a pedestrian walkway.

7. All activities must be supervised.

8. The sign board is to be placed with proper barricading.

9. No equipment operation shall be permitted during adverse weather conditions

10. All equipment shall switch on rotating warning flashing lights while in operation

11. The movement of plant and equipment shall be carried out only after getting the required permission from the concerned authority.

Activity No. 2: Heavy Lifting operation-lifting of the crane parts by using Mobile Crane.

Hazards

1. Failure of lifting gears and crane

2. Improper rigging

3. Improper positioning of the crane.

4. Usage of defective lifting gears.

5. Reversing vehicles.

6. Poor communication between operator and rigger.

7. Poor visibility due to the structure or building

8. The collision between other cranes in the same radius or height.

9. Unstable ground condition

10. Suspended load

11. Unauthorized operation of lifting equipment.

12. Incompetent riggers/operators/slingers

13. Prolonged duty

14. Overhead lifting operation

15. Manual handling of heavy materials.

16. Health hazards from oil, and grease leaks.

17. Moving mechanical parts of equipment.

Risk

1. Injury /fatality due to equipment failure

2. Injury due to Falling objects due to failure of lifting slings

3. Injury due to workers being hit by vehicles.

4. Serious injury or fatality to workers by the uncontrolled load

5. Injuries due to entanglement between load and lifting gears.

6. Property damage due to equipment failure

7. Fatality or serious injury due to a fall from height by the failure of equipment or lifting gears.

8. Injury/fatality due to workers being hit by the load.

9. Injury/fatality due to crane collision and materials falling on workers.

10. Injury due to toppling of equipment.

11. Property damage.

12. Fatality/injury due to the suspended load being dropped due to equipment failure.

13. Injury due to equipment failure by an authorized crane operator.

14. Injury to workers due to equipment/load failure.

15. Property damage.

16. Fatigue

17. Injury due to workers being hit by the load or lifting equipment

18. Muscle cramps

19. Body pain.

20. Injury due to Slip and fall on a slippery surface from oil/grease leakage

21. Injury due to entanglement with rotating parts of the equipment during maintenance/operation

Control Measures

1. Closed supervision must be placed.

2. Proper PPE should be provided.

3. Proper manual material handling methods are to be used.

4. Pre-inspection of all lifting gears

5. Lifting gears should be certified and color-coded

6. Crane operators must have traffic licenses and riggers shall be certified

7. The tagline is to be provided to control the movement of the load

8. Provide safety warning signs and the area should be barricaded.

9. No load shall be lifted above workers.

10. Proper access and egress are to be provided and free of obstruction to be used in case of emergency.

11. Task safety briefing shall be done before beginning the activity.

12. A lifting operation permit shall be raised.

13. Proper communication must be ensured between the operator and riggers.

14. Proper illumination should be available.

15. Provide radio communication to riggers and operators.

16. Proper supervision by the nominated lifting supervisor.

17. Provide an anti-collision system in tower cranes.

18. Lifting supervisor to ensure that cranes are not set on/near any underground services.

19. Proper and routine maintenance is to be carried out for all lifting equipment.

20. A periodic health check-up is required for operators.

21. All operators and riggers must be certified by an authorized 3rd party for competency.

22. Ensure all operators and riggers are experienced and trained well to carry out the lifting operation safely.

23. Ensure that operators get enough rest.

24. Proper slinging methods are to be used.

25. Tagline to be provided to control the unwanted movement of the load.

26. Ensure to provide exclusion zones.

27. Approved manual handling technique to be briefed to workers.

28. Use mechanical aids as practicably as possible.

29. Get additional help from co-workers while lifting heavy materials.

30. Hold the load firmly to avoid any slip and fall injury.

31. Clean the oil leaks immediately by using proper oil spill kits.

32. Ensure to switch off the engine before commencing any maintenance job.

33. Ensure all rotating parts are provided with safety guards.

34. Never use a loose dress while working with rotating parts

Activity No.3: Erection of Tower Crane sections/Boom.

Hazards

1. Man falling.

2. Crane parts falling.

3. Material / Tools falling.

4. Physical hazards while handling the materials

5. Material shifting manually.

6. Trip and fall due to poor material management.

Risk

1. Fatality/serious injury due to falling from height.

2. Fatality/ serious injury due to materials/parts falling on workers below.

3. Physical injury while material handling.

4. Back Injuries

5. Cut to Finger

6. Strain

7. Musculoskeletal Injuries

Control Measures

1. The Tower crane must be erectile by trained and experienced workers.

2. The area below the area of the crane must be barricaded and warning sign boards to be provided.

3. Adequate access egress must be provided.

4. All workers must be wearing and using full body safety harness 100 % tie off by using a harness with a double lanyard.

5. Secure all tools properly to prevent falling.

6. No load shall be lifted above workers.

7. Task safety briefing shall be done before beginning the activity.

8. A lifting operation permit shall be raised.

9. Lifting points shall be as per the design only.

10. Do not climb the ladder with materials

11. All personnel are provided with TBT before work.

12. The area underneath the erection activity must be restricted for entry.

13. Post warning signs and provide close supervision

14. Training shall be given by Tower crane experts regarding handling and lifting.

15. No lifting in adverse weather conditions like heavy wind and rain.

16. Erection of the tower crane section must be under the supervision of the lifting-nominated engineer.

Activity No.4: Working at Heights.

Hazards

1. Structure collapse.

2. Materials and tools falling.

3. Fall from height.

4. Access/ Egress

5. Falling mobile equipment.

6. Ladder.

Risk

1. Injury/fatality due to

2. Men falling

3. Injury/fatality due to materials falling.

Control Measures

1. All workers who are working at height must use a safety harness and be anchored to a solid point.

2. The harness is to be inspected before use.

3. Barricade the area below and sign board to be provided.

4. TSA is to be briefed to workers before starting the job.

5. Proper supervision should be available always.

6. Keep the access and egress free from any obstruction.

7. Barricade the area.

8. Proper signboards are to be placed.

9. No work will be carried out in adverse weather conditions.

10. Secure all tools to prevent them from falling.

11. Do not carry any materials while climbing the ladder.

Activity No. 5: Manual Handling-Handling of Tools.

Hazards

1. Sharp Edges.

2. Slip/Trip/Fall.

3. Unsafe posture.

Risk

1. Back Injuries.

2. Cut Injuries.

3. Strain.

4. Musculoskeletal Injuries.

Control Measures

1. Any lifting tasks shall be carried out by persons physically capable to do so

2. No employee should be asked to carry loads above his capacity and in any case, no load shall exceed 30kg per man

3. The mass of the load is more than to be equally shared.

4. Deploying enough personnel for lifting shall be appointed to the task depending upon the type of load to be lifted.

5. Use an easy mode of transport like a trolley etc.

6. Load not to be lifted above your shoulder height.

7. Keep your fingers away from the pinch point while placing the load.

8. Area is to be illuminated with adequate lighting.

9. Proper personnel protective equipment is to be used while manually handling material and loads.

Activity No. 6: Working with hand tools (hammer, spanner)

Hazards

1. Damaged warn-out hand tools.

2. Flying objects.

3. Using the incorrect type of tools.

Risk

1. Fatigue

2. Trigger finger

3. Cuts and abrasions

Control Measures

1. Defective tools should not be issued or used to perform the task, to be checked by the storekeeper.

2. All tools should be inspected by a competent person and colour coded.

3. Don’t extend the spanner by using a pipe as an extension bar.

4. Hand tools shall be free from oil, grease &, etc.

5. Chisel’s head shall have a safety cap to avoid finger injury.

6. Never use a file as a level.

7. Never use a screwdriver as a chisel.

8. Use eye/face protection when there is a flying material hazard, and wear gloves while required to protect the hands.

9. Use the right tools for a job.

Activity No. 7: Working during heavy windy weather/rainy weather

Hazards

1. Lifting operation

2. Unsecured materials

3. Working at a height

4. Flying objects

5. Dust

6. Working on crane mast

Risk

1. Fatality/ serious injury

2. Injury due to workers being hit by flying objects.

3. Injury resulting from falling objects while erection.

4. Eye injury.

5. Respiratory sickness due to dust inhalation.

6. Injury to workers

7. Men and materials falling down

Control measures

1. All lifting operations shall be stopped.

2. All construction materials must be secured well to avoid flying away.

3. Erection activities shall be stopped during heavy windy days.

4. All activities on slab edges and top slabs must be suspended until the wind speed is within the allowable limit.

5. All workers must report to the basement if the wind speed is above the allowable limit.

6. Nobody is allowed to rest in a temporary rest area except in the basement.

7. Goggles must be provided to workers.

8. Dust masks must be used in a dusty climate.

Thanks for your precious work which help us and many others again thanks